Blister Packaging: An Effective Solution for Protecting and Distributing Products

|

| Blister Packaging |

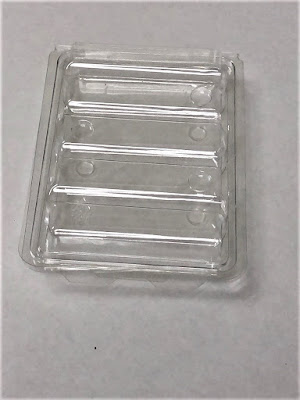

What is Blister Packaging?

Blister packaging is a term used to describe plastic packaging with a cavity or

pocket that is usually made of aluminum foil, plastic, or paperboard to hold an

item. A paper or plastic backing is heat sealed or cold formed over the blister

to retain the product. This type of packaging provides visibility for products

and helps prevent damage and tampering.

Benefits of Blister Packaging

Protection Against Damage: The sturdy plastic or foil that forms the cavity

protects products from damage caused by vibration and shock during

transportation and handling. It prevents crushing and contamination that can

occur with other packaging types.

Visibility and Product Promotion: Blister

Packaging prominently display products through clear plastic windows.

This allows consumers to easily view items before purchase and helps promote

branding and product information on the package.

Tamper Evidence: Many blister packs have been designed with tamper evident

features like peelable backing films or breakaway seals to indicate if a product

has been opened before. This builds trust with customers.

Shelf-Ready Packaging: Due to their construction, blister packs are easy for

retailers to display and stock on shelves without additional packaging. They

use shelf space efficiently and catch the eye of store customers.

Convenience: Once opened, the packaging can function as a convenient carrying

case for products like toys, small electronic devices, hardware items and more.

This enhances the consumer experience.

Customization: Blister packs can be customized with specialized designs,

materials and production techniques to meet the needs of various products and

industries. Attributes like child resistance and senior friendly features can

be incorporated.

Designs for Product Types

Certain blister pack designs have been developed to suit unique requirements of

different product categories:

Healthcare/Pharmaceutical Products: Child-resistant and senior-friendly

features are utilized. Moisture barrier properties protect pills and capsules.

Serialized printing is applied for anti-counterfeit measures.

Small Hardware: Parts are securely held in formed cavities and the packs

withstand warehousing and shipping vibrations better than other types.

Food Items: High-barrier films shield products from oxygen, moisture, and other

contaminants. Tamper evidence and recloseability allow for partial consumption.

Daily Use Accessories: Snug-fitting shapes of memory cards, thumb drives, and

batteries are easily depicted. Peel-push opening seals provide quick access.

Manufacturing Processes

Several manufacturing techniques are used to produce customized blister packs

depending on design complexity and volume requirements:

Thermoforming: A sheet of clear plastic is heated and formed into cavities over

a mold using vacuum, air pressure, or mechanical processes. It is then sealed

to a backing.

Die-Cutting/Cold Forming: Paper or plastic stock rolls are fed into machines

that use steel rule dies to cut precise shapes. Pressure forms cavities without

heat.

Rotary Pressure Forming: Continuous webs of material pass between a male and

female roller with cavities. Pressure forms pockets in a high-speed,

roll-to-roll process.

Thermoforming/Pouch Making: Forming and sealing are integrated into one process

using continuous films sealed along fin seals rather than flat panels.

Injection/Insert Molding: Plastic resins are injected directly into molds

containing product components for complex, integrated designs.

Automated Production and Quality Control

Modern blister packaging lines feature automated machinery that integrates

forming, insertion, printing, sealing and quality assurance checks into one

streamlined process. In-line vision systems and barcode scanning ensure

consistent quality and that the right product is placed in each cavity. Robotic

product loaders further speed throughput. Real-time data collection allows for

quick identification and resolution of issues. With computer-controlled

thermoformers, even small batches can be produced cost-effectively. Automation

greatly improves efficiency, product security, and manufacturing precision over

hand-assembly methods.

Blister packaging provides an effective solution for safely distributing and

promoting a wide range of items. The tamper evident, high clarity format

secures goods during transportation while attracting consumer attention on

shelves. Customizable designs support distinct product profiles and industries.

Streamlined manufacturing capabilities deliver consistent, quality packages.

With ongoing development, the applications and benefits of blister packaging

will continue to expand in the growing packaging sector.

Get More Insights on Blister Packaging

Comments

Post a Comment